PRODUCT

IKING Stainless Steel Threaded Stud for Arc Stud Welding

High-quality stainless steel threaded studs, designed for fast, strong, and corrosion-resistant welded connections. Suitable for applications such as transformers and control cabinets, they are perfectly compatible with stud welding systems, ensuring safe and durable performance.

1. Material:Made from premium stainless steel for superior rust resistance.

2. Easy to install:Precision threads ensure secure fit and easy installation.

Product Introduction

Stainless steel threaded studs are thoughtfully designed fasteners, made specifically to work with stud welders and other welding equipment. These threaded studs attach to all types of metal base materials quickly and dependably, forming strong, long-lasting connections that stand the test of time. Made from top-quality stainless steel, stainless steel threaded studs hold up well against rust, have great pulling strength, and are built to last — perfect for regular use in tough industrial settings over the long haul.

Product Advantages

1. Crafted from high-quality stainless steel, stainless steel threaded studs offer excellent rust resistance and reliable mechanical performance.

2. When used with compatible stud welders, stainless steel threaded studs form a strong metallurgical bond through advanced arc stud welding, ensuring steady strength and stability every time.

3. Threaded studs work with most welding equipment (including standard stud welders), making them a versatile choice for all kinds of industrial and structural projects.

4. The precise threads on threaded studs ensure a secure fit, easy assembly, and long service life for any stainless steel threaded stud installation.

Product Parameters

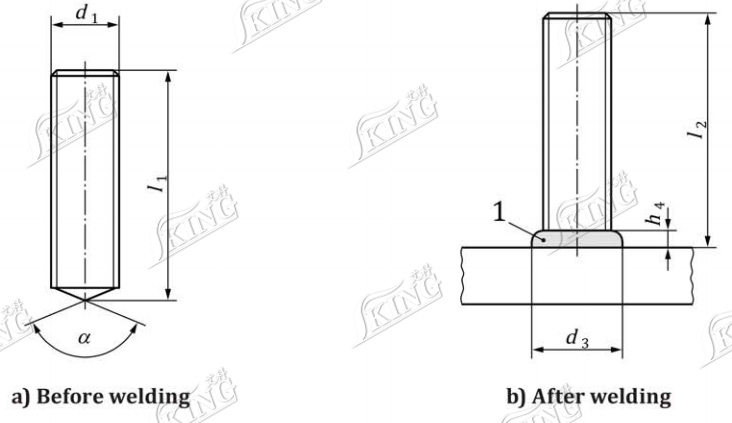

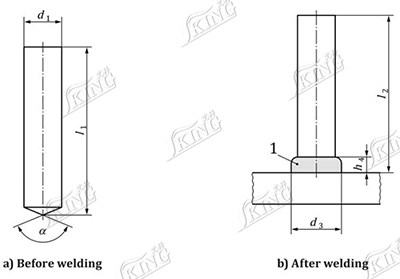

1.Fully-threaded stud (FD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

|

d3ᵇ |

8.5 |

11 |

13 |

16 |

21 |

26 |

|

h4ᵇ |

4 |

4 |

4 |

5 |

7 |

7 |

|

α ± 7° |

140° |

|||||

|

l1 ± 1ᵃ |

l2 + 2.1 |

l2 + 2.2 |

l2 + 2.3 |

l2 + 2.8 |

l2 + 3.5 |

l2 + 3.8 |

|

l2 |

15–100 |

15–100 |

15–100 |

25–100 |

30–100 |

40–100 |

|

a Length l1 applies to angle 140°only(without tolerance). |

||||||

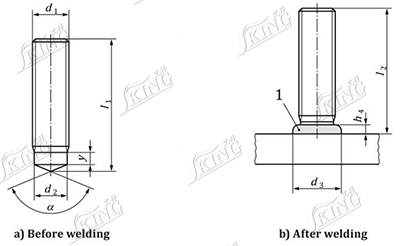

2. Virtually fully-threaded stud (MD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

|

d2 ± 0.1 |

5.35 |

7.19 |

9.03 |

10.86 |

14.6 |

|

d3ᵇ |

9 |

9.9 |

12.5 |

14.5 |

17.8 |

|

y |

5.5 |

6 |

6.5 |

7.5 |

11 |

|

h4ᵇ |

3.5 |

3 |

3.4 |

4.2 |

5.8 |

|

α ± 7° |

140° |

||||

|

l1 ± 1ᵃ |

l2 + 2.1 |

l2 + 2.2 |

l2 + 2.3 |

l2 + 2.8 |

l2 + 3.5 |

|

l2 |

15–100 |

15–100 |

15–100 |

20–100 |

25–100 |

|

a Length l1 applies to angle 140°only(without tolerance). |

|||||

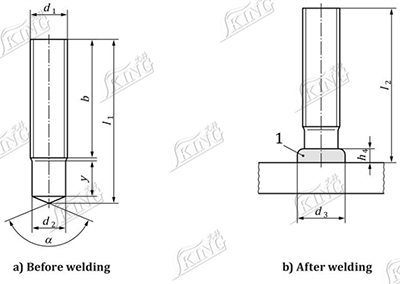

3. Partially threaded stud (PD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

|||||||

|

d2 ± 0.1 |

5.35 |

7.19 |

9.03 |

10.86 |

14.6 |

18.38 |

22.05 |

|||||||

|

d3ᵇ |

8.5 |

10 |

12.5 |

15.5 |

19.5 |

24.5 |

30 |

|||||||

|

h4ᵇ |

3.5 |

3.5 |

4 |

4.5 |

6 |

7 |

10 |

|||||||

|

α ± 7° |

140° |

|||||||||||||

|

l1 ± 1ᵃ |

l2 + 2.1 |

l2 + 2.2 |

l2 + 2.3 |

l2 + 2.8 |

l2 + 3.5 |

l2 + 3.8 |

l2 + 4.5 |

|||||||

|

l2 |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

|

15 |

9 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

20 |

9 |

- |

9 |

- |

9.5 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

25 |

9 |

- |

9 |

- |

9.5 |

- |

11.5 |

- |

- |

- |

- |

- |

- |

- |

|

30 |

9 |

- |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

- |

- |

- |

- |

|

35 |

- |

20 |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

15.5 |

- |

- |

- |

|

40 |

- |

20 |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

15.5 |

- |

- |

- |

|

45 |

- |

20 |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

15.5 |

- |

- |

- |

|

50 |

- |

20 |

- |

40 |

- |

40 |

- |

40 |

13.5 |

- |

- |

35 |

20 |

- |

|

55 |

- |

20 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

- |

|

60 |

- |

20 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

- |

|

65 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

- |

|

70 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

50 |

- |

50 |

- |

50 |

|

80 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

50 |

- |

50 |

- |

50 |

|

100 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

80 |

- |

70 |

- |

70 |

|

140 |

- |

- |

- |

40 |

- |

80 |

- |

80 |

- |

80 |

- |

70 |

- |

70 |

|

150 |

- |

- |

- |

40 |

- |

80 |

- |

80 |

- |

80 |

- |

70 |

- |

100 |

|

160 |

- |

- |

- |

- |

- |

80 |

- |

80 |

- |

80 |

- |

70 |

- |

100 |

|

a Length l1 applies to angle 140°only(without tolerance). |

||||||||||||||

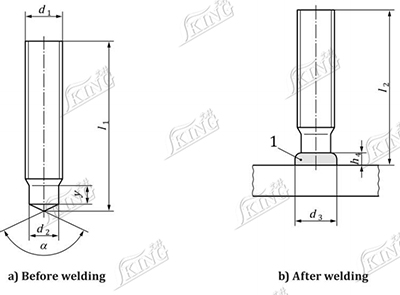

4.Threaded stud with reduced shaft (RD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

|

d2 ± 0.1 |

4.7 |

6.2 |

7.9 |

9.5 |

13.2 |

16.5 |

20 |

|

d3ᶜ |

7 |

9 |

11.5 |

13.5 |

18 |

23 |

28 |

|

h4ᶜ |

2.5 |

2.5 |

3 |

4 |

5 |

6 |

7 |

|

y + 2P |

4 |

4 |

5 |

6 |

7.5/11ᵃ |

9/13ᵃ |

12/15ᵃ |

|

α ± 7° |

140° |

||||||

|

l1 ± 1ᵇ |

l2 + 2.0 |

l2 + 2.2 |

l2 + 2.4 |

l2 + 2.8 |

l2 + 3.6 |

l2 + 3.9 |

l2 + 4.7 |

|

l2 |

15–100 |

15–100 |

15–100 |

20–100 |

25–100 |

30–100 |

40–100 |

|

The dimensions after the oblique stroke shall apply if ceramic ferrules. |

|||||||

5. Unthreaded stud (UD)

|

d1± 0.1 |

6 |

8 |

10 |

12 |

14.6 |

16 |

|

d3ᵇ |

8.5 |

11 |

13 |

16 |

18.5 |

21 |

|

h4ᵇ |

4 |

4 |

4 |

5 |

6 |

7 |

|

α ± 7° |

140 |

|||||

|

l1 ± 1ᵃ |

l2+2.4 |

l2+2.6 |

l2+2.8 |

l2+3.4 |

l2+3.9 |

l2+3.9 |

|

a Length l1 applies to angle 140°only(without tolerance). |

||||||

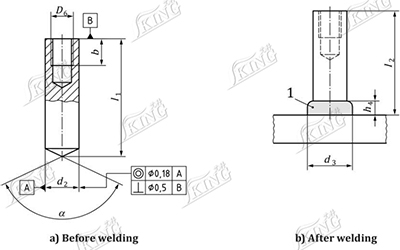

6.Stud with internal thread (ID)

|

D6 |

M5 |

M6 |

M8 |

M8 |

M10 |

M10 |

M12 |

|

d₂ ±0,1 |

10 |

10 |

12 |

14.6 |

14.6 |

16 |

18.38 |

|

d₃ᵇ |

13 |

13 |

16 |

18.5 |

18.5 |

21 |

23 |

|

b+2P |

7.5 |

9 |

12 |

15 |

15 |

15 |

18 |

|

h₄ᵇ |

4 |

4 |

5 |

6 |

6 |

7 |

7 |

|

l₂ min |

15 |

15 |

20 |

25 |

25 |

25 |

30 |

|

α ±7° |

140° |

||||||

|

l₁ ±1ᵃ |

l₂ min + 2,3 |

l₂ min + 2,3 |

l₂ min + 2,8 |

l₂ min + 3,5 |

l₂ min + 3,5 |

l₂ min + 3,5 |

l₂ min + 3,7 |

|

a Length l1 applies to angle 140°only(without tolerance). |

|||||||

Welding process

A. Stud is loaded into the weld tool and properly positionedagainst the base metal.

B. Trigger is depressed; Stud lifts, creating arc.

C. Arcing period completed and stud is plunged into moltenpool.

D. Weld is complete, weld tool is withdrawn andferrule removed for inspection.

Materials and mechanical characteristics offinished studs

|

Symbol |

Material/ material group/ property class |

Standard |

Mechanical properties of the finished stud |

|

FD |

4.8 |

IS0 898-1c |

See ISO 898-1 |

|

A2-50, A2-70,A4-50, |

ISO 3506-1c |

See ISO 3506-1 |

Application

Stainless steel threaded studs see wide use in metalworking fields — such as building steel structures, manufacturing ships, constructing bridges, and making machinery. Pair stainless steel threaded studs with a professional stud welder or other suitable welding equipment, and they install smoothly whether you’re welding by hand or using automated setups. These threaded studs also support heavy loads reliably and help get industrial work done more efficiently.